When it comes to keeping our buildings weathertight and preventing unwanted airflow, the humble air seal plays a vital role. The duo of sealant and backing rod are one option to achieving this around windows and doors. But how do they work together, and why bother with both?

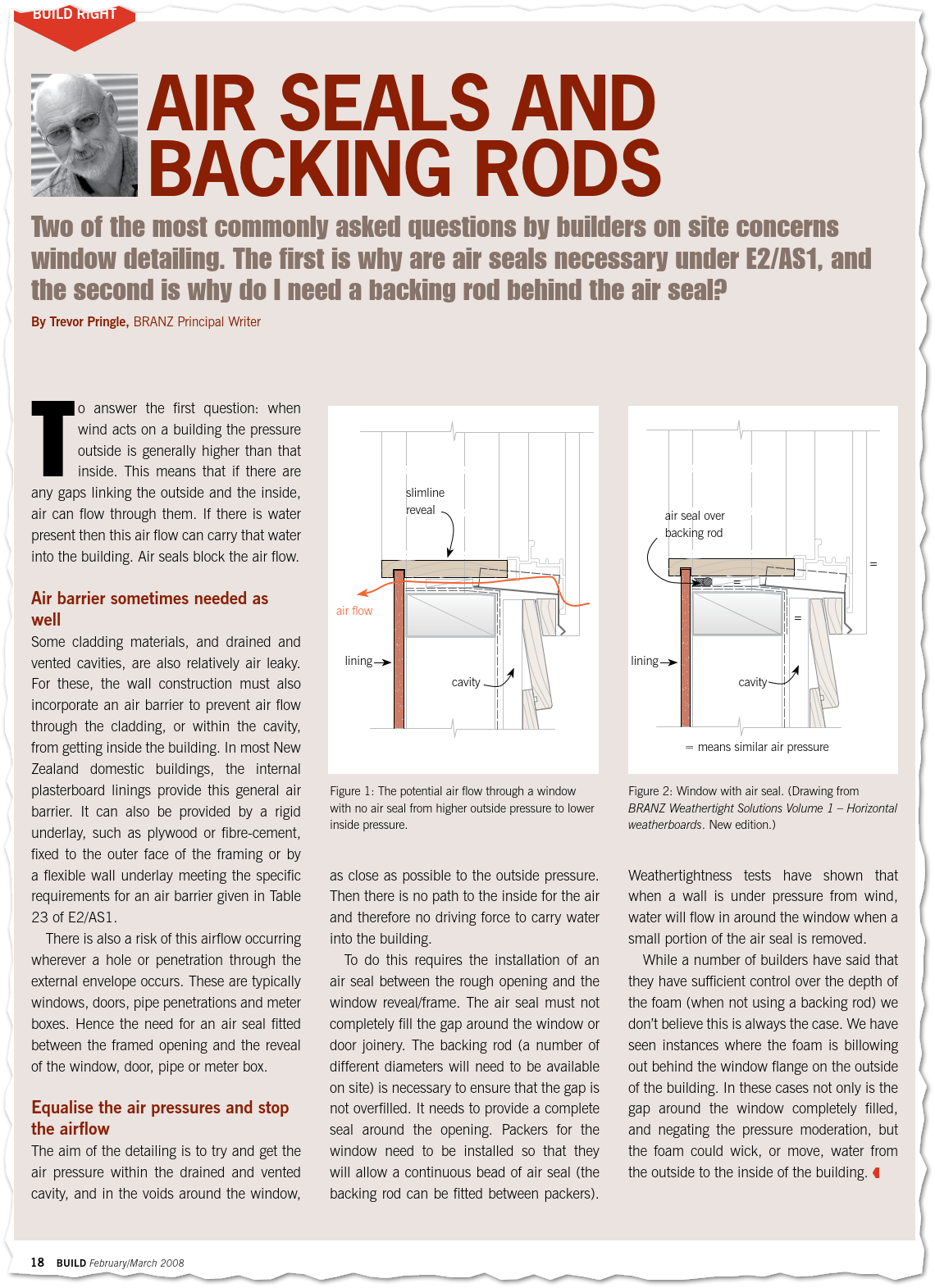

One of the primary reasons we meticulously install an air seal is to block airflow and water driven by wind pressure. When wind pushes against a building, the higher external pressure can force air, and any accompanying water, through gaps in the building envelope. This specific detailing is aimed at getting the air pressure within the drained and vented cavity, and the voids around the window, as close as possible to the outside pressure. By equalizing these pressures, there’s no driving force to push air and water into the building. An effective air seal stops this flow allowing the water to safely drain away within the vented cavity.

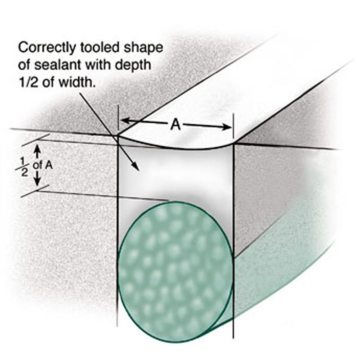

Now, where does the backing rod come in? It’s tempting to think it’s just there to control how much sealant we use, but its role is more nuanced and WAY more important. The backing rod ensures that the sealant makes an hourglass shape. This shape is thin in the middle (half the gap width) and wider at the edges – the thin middle stretches without pulling the thicker edges off of the surfaces they are stuck too. This article by Sika “Hour-Glass” and Tension: Caulk and Backer Rod’s Achilles Heels correctly points this out. I know this seems like a overly complex look at a simple detail but if your builders do not get this right your windows are much more likely to leak.

Image from Sika Hourglass and Tension in Backer Rods

What about using polyurethane (PU) gun foam to seal this gap? I agree with the BRANZ Build Feb/March 2008 article that if the gap is completely filled, the foam itself could potentially wick water from the outside to the inside So, why use foam sealant in the first place? Because it’s a quick (and thus cheap) way to block the air flow through those inevitable gaps around penetrations like windows and doors. My main concern with foam, even with a backing rod, is durability when the building moves over time. Tapes and sealant plus backing rod (when installed correctly) can manage movement and I’m not sure that PU gun foam will stay sealed as well with the same amount of movement. This is why we usually specify tapes in our Passive House projects. That said we have had buildings use sealant plus backing rod with a skilled set of tradies to meet the Passive House air tightness requirements.