Taupaki House Auckland

Project Team

Architecture & Passive House Design Space Division - spacedivision.com

Builder Rusa Construction - rusaconstruction.co.nz

Certifier Sustainable Engineering Ltd – sustainableengineering.co.nz

This beautiful new home in the Auckland region was designed as a spec build for Rusa Construction, headed by a builder-turned-developer who had been long interested in the Passive House standard. This rural subdivision was his opportunity to build his first Passive House home and he proved himself an excellent client as well as a conscientious builder.

The builder costed the project at a very early stage of design, when a hand sketch had just been digitised. This was a detailed analysis, which also compared building with SIP to a conventional timber frame construction. The need to reduce costs was identified and the design was simplified by creating a rectangular form with deep overhangs to the west to shade extensive glazing from direct summer sun.

The architectural practice had designed Seaward House (certified Passive House, featured here) but this and a concurrent project were the first for which the practice also undertook the Passive House design. Thermal modelling offered significant insights that influenced material choices and specifications. The benign Auckland climate offers designers more flexibility: in general keeping cool is more of a challenge than staying warm. Modelling different options in PHPP challenged initial assumptions and indicated the benefit of reducing underslab insulation. The high glazing ratio makes the most of the rural views, while operable shading protects from heat gain in summer.

The construction team had the perfect attitude for first-time Passive House builders: curious, keen and diligent. The architects report some of them were swotting up at night and bringing back insights to share with their teammates. Training opportunities offered by Pro Clima were taken up. Sub-trades were carefully briefed and oversight maintained with regard to penetrations of the airtight layers by services.

The entire staff at Space Division turned out to install the airtight membrane, an admirable act of hands-on, applied learning—read more here.

This new home was sensitively designed in relation to its beautiful rural location, although those expansive views come with the usual complications of more earthworks plus integrating rainwater harvesting and on site management of grey and black water.

The cladding is a product called Taxon, thermally modified tulipwood. This process is an alternative to chemical treatment such as copper-chrome-arsenic (CCA) and produces timber with increased resistance to fire, rot and insects and which improves timber density, stability and strength.

The home’s new owners are very comfortable and happy. A low-wall heat pump was installed but has been barely used for either heating or cooling.

Passive House Metrics

- Heating Demand11.9 kWh/m2/year

- Heating Load9.1 W/m2

- TFA206.3m2

- Form Factor3.3

- Air leakage @ 50Pa0.6 ACH/hour

- PER demand33.6kWh/m2/year

Passive House Database - 7570

Construction Details Average Values

- U-value External Walls0.29 W/(m2K)(R3.49)

- Cladding/Cavity/GIB Weatherline/140mm R3.6 timber stud/Intello/Uninsulated 45mm service cavity/GIB

- U-value Floor0.54W/(m2K)(R1.86)

- Concrete slab on 60mm S-grade EPS

- U-value Roof 0.14W/(m2K)(R7.36)

- Roofing on purlins/7mm Plywood/300mm rafters R5.2+R2.2 fibreglass/uninsulated service cavity/GIB

- U-value Glass1.18 W/(m2K)(R0.85)

- Viridian Lightbridge 4/16/:4 90%Ar

- U-Windows1.5 W/(m2K)(R0.6)

- Optimal Timber Windows Abodo Frames

- Ventilation Efficiency88%

- Zehnder Group Nederland B.V. - ComfoAir Q350 HRV, Comfort Vent Q350 HRV

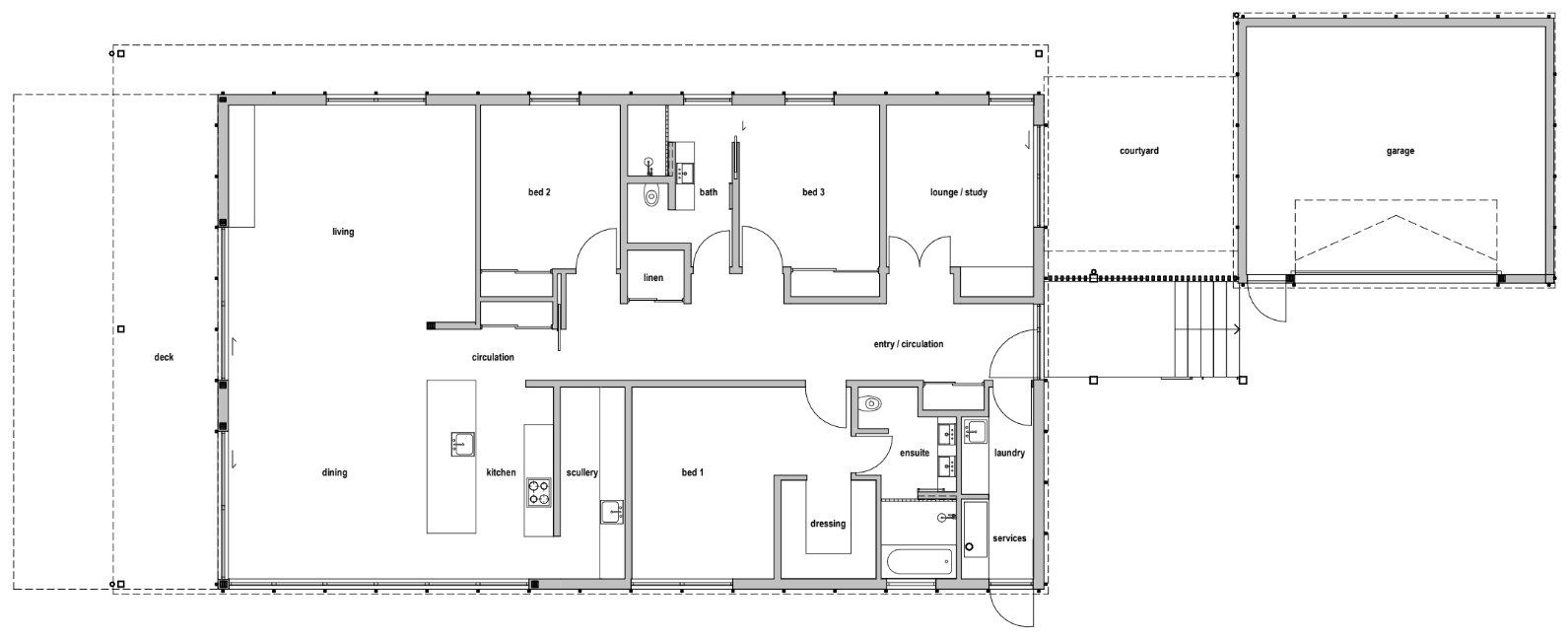

Floor Plan

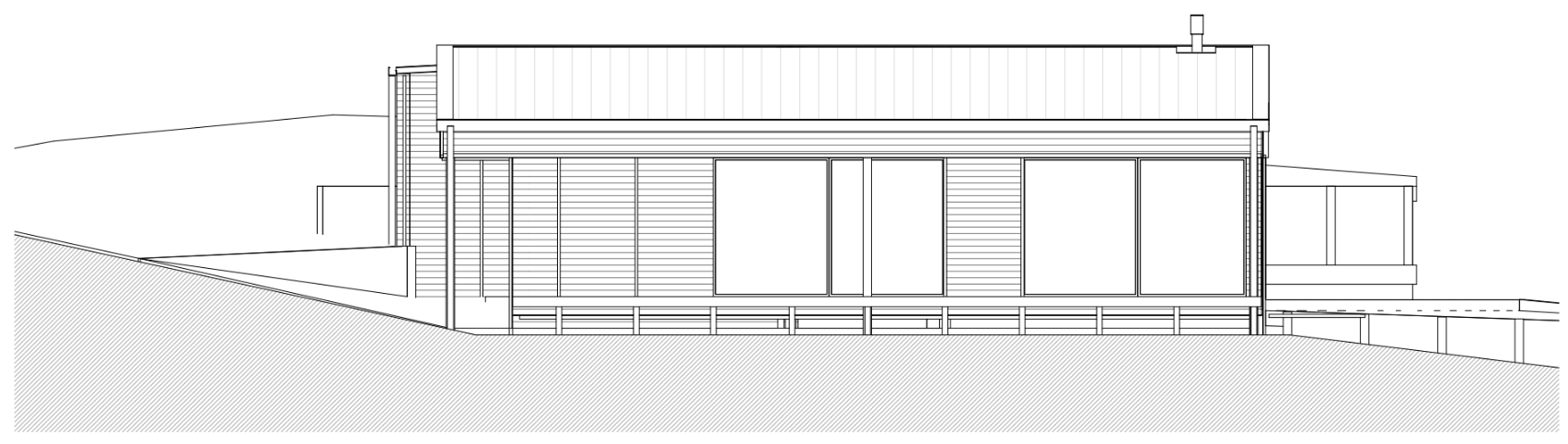

West Elevation

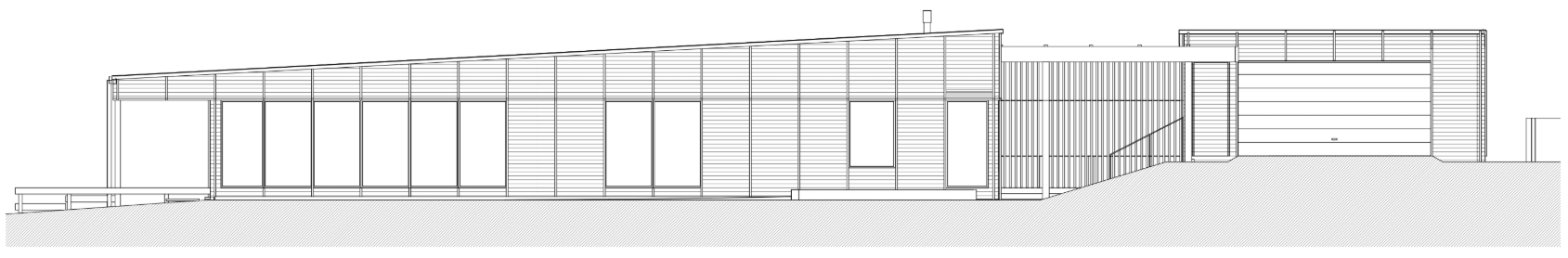

South Elevation

Photos of completed home by Sam Hartnett

Photos of completed home by Sam Hartnett