The heat pump worksheet in PHPP isn’t user-friendly but it’s not impossible. PHI don’t provide anything in the way of official step-by-step guidance because the Germans expect it to be completed by a mechanical engineer! OK, I am a mechanical engineer but I don’t think we should be required on a simple project like a single family home. That said, in PHPP9, no-one ever submitted this data correctly the first time and not for lack of honest effort on the part of some really smart Passive House designers.

Now we’re working with PHPP10. Heat pump calcs are still hard but it is slightly quicker just because PHPP10 is better. The other good news is Sustainable Engineering’s team has put together a how-to guide illustrating how to enter the data for a simple high-wall heat pump. Work through that, and after your first time, it shouldn’t take long.

We’re really focused on easing the pinch points when it comes to modelling and certifying high-performance homes. Before we jump into the details, a couple of important observations. Heat pumps in a high-performance building run for fewer days of the year compared to those in buildings built only to the Code. The heat pump COP will be worse in a Passive House, compared to what’s on the sticker. That’s counter-intuitive perhaps, but it is because the heat pump is only required when outdoor temperatures are very low. In an ordinary house next door, the heat pump is also running on slightly warmer cold days and that affects the average of its performance.

Energy modelling is useful to the extent it is accurate and that means reflecting what actually happens, not something theoretical. On board? Right, let’s corral some data into the right places.

PHPPv10 allows you to directly enter heat pump data point-by-point; not dissimilar to the previous version of the software but an intermediate spreadsheet is no longer required. This saves some time but there’s still a lot of data to enter and it assumes you have a reasonable understanding of how HVAC systems work.

Note: this guidance assumes you are specifying a simple air-to-air system (a “normal” heat pump as typically found in New Zealand homes). If you’re looking at something else, you need some experience with HVAC systems design in order to understand how the system works and how best to model the physics in PHPP. If you don’t, then it is a case of calling in a mechanical engineer.

Do start by reading section 18.8 in the PHPP10 manual (behind a paywall here). Ideally you’d have eight test points for heating and three or more for cooling. If the unit has re-heating for dehumidification, more data is required.

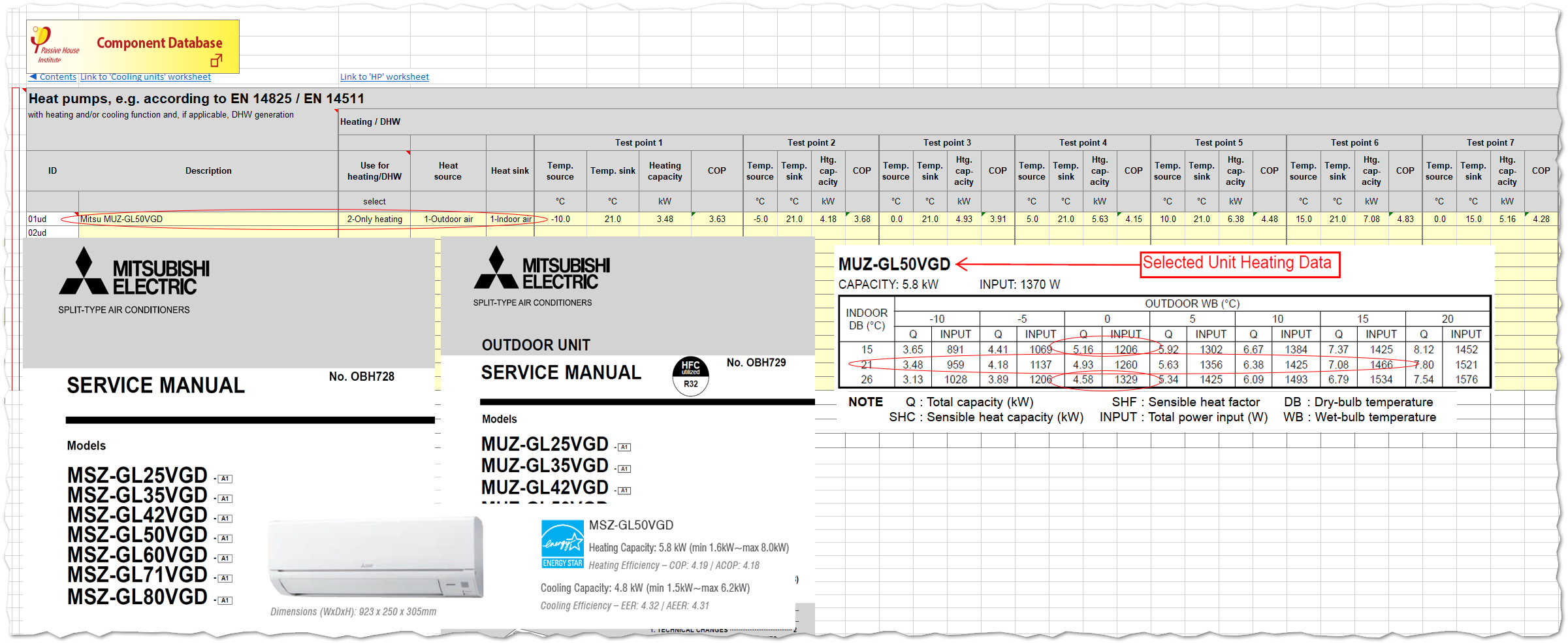

The test data you need can be found in the technical manuals for the specified outdoor and indoor heat pump units. Find the test data for heating and cooling performance as well as airflows for the indoor unit. Pro tip: screenshot this data and paste it into your spreadsheet so it’s easy to find when it comes to doing the paperwork for certification.

We start with the component sheet.

HEATING

a. Name your HP to match the manufacturer’s description. Be very specific.

b. Select ‘2- Only heating’ for an air-to-air heat pump. For source, select ‘1-Outdoor air’ and for sink ‘1-Indoor air’.

c. Enter the Heating test points. Make sure to cover the climate range for your location – focus on 21C internal temperature but I like to put a few points above and below as well. See below. Remember COP=Heating Power/Input Power or the heating you get divided by the electricity you pay for i.e. COP of 3 means you get three kW of heat for one kW of electricity.

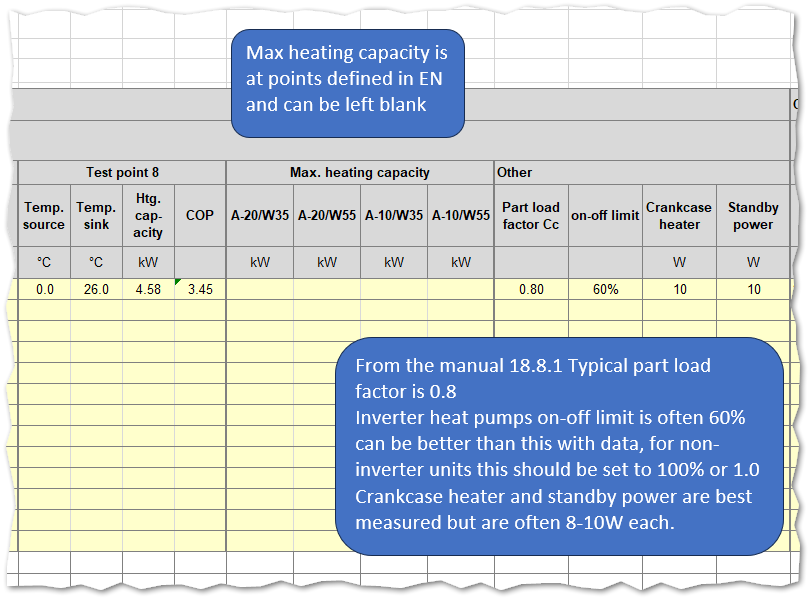

d. Note Max. heating capacity is at points defined in EN and can be left blank.

d. Note Max. heating capacity is at points defined in EN and can be left blank.

e. The other section needs to be filled in. From the manual 18.8.1 Typical part load factor is 0.8. Inverter heat pumps on-off limit is often 60% can be better than this with data, for non-inverter units this should be set to 100% or 1.0. Crankcase heater and standby power are best measured but are often 8-10W each.

COOLING

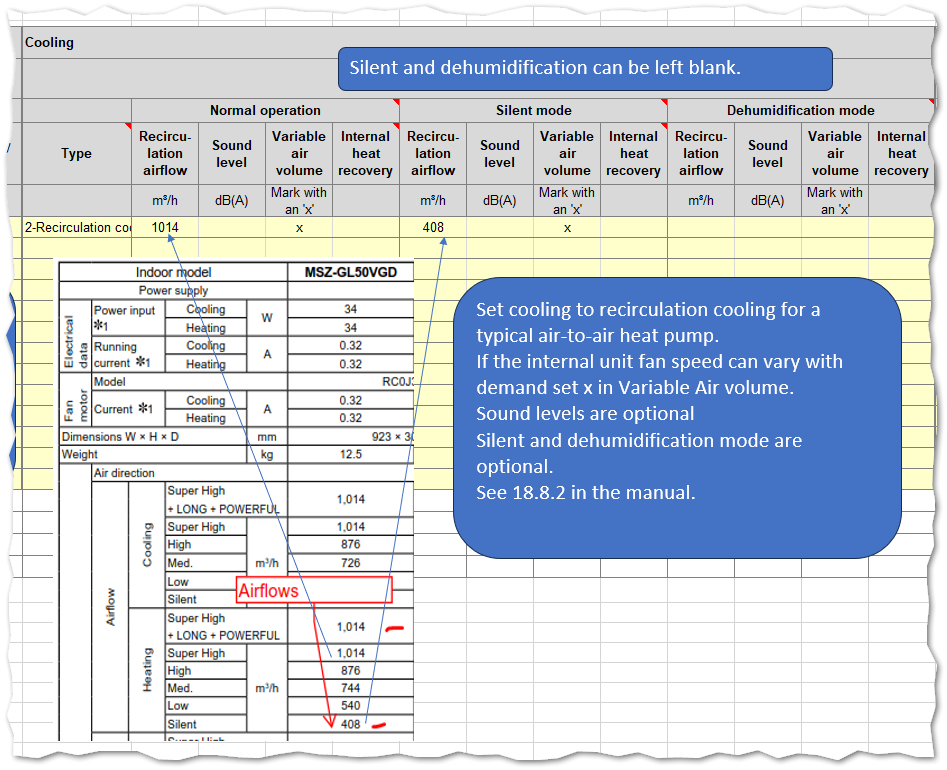

f. Select recirculation cooling for an air-to-air unit.

g. Set airflow to maximum for normal and silent

h. If the indoor unit fan speed can vary with load put an ‘x’ in Variable Air volume. Note silent and dehumidification can be left blank but I’d recommend putting silent airflow in and using this for the design.

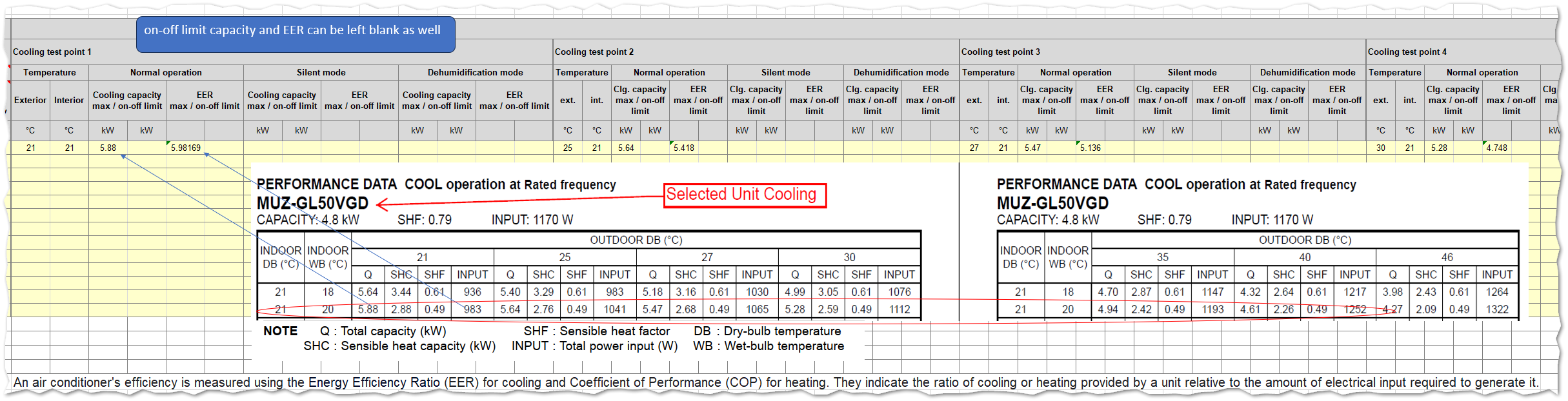

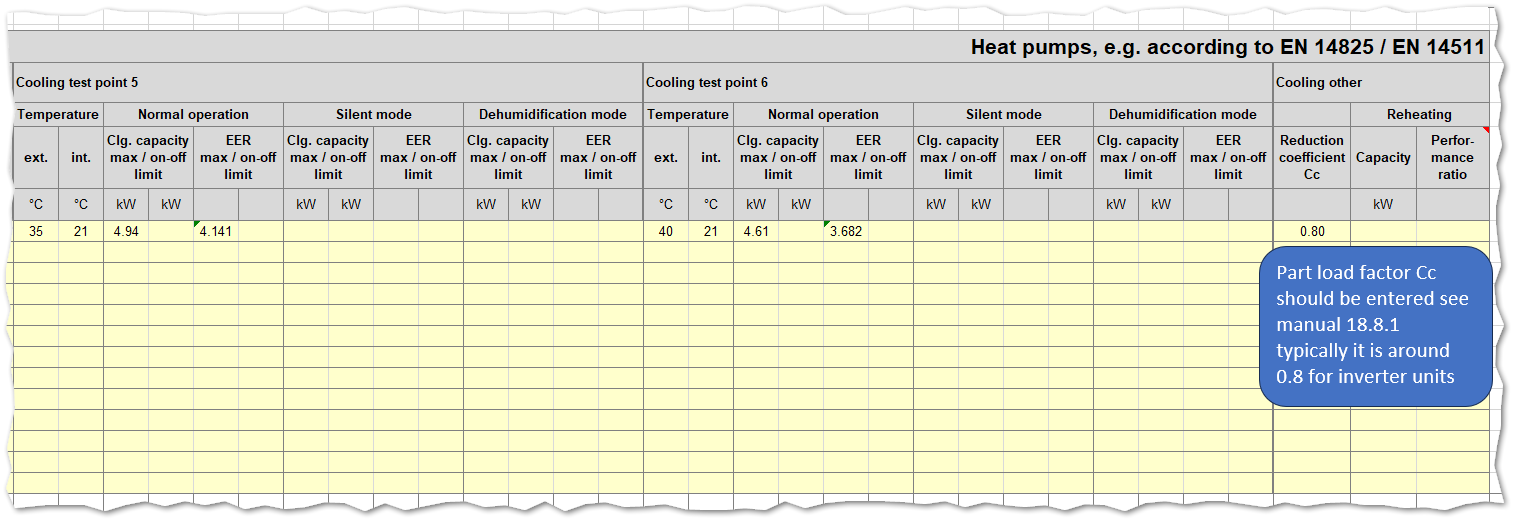

i. Enter the cooling data points. Remember EER=Cooling power / Input Power. I’d recommend entering as many data points as will fit. Note you can leave the on-off limit capacity and EER blank as well.

j. Enter part load factor Cc see manual 18.8.1 typically it is around 0.8 for inverter units and 1.0 otherwise.

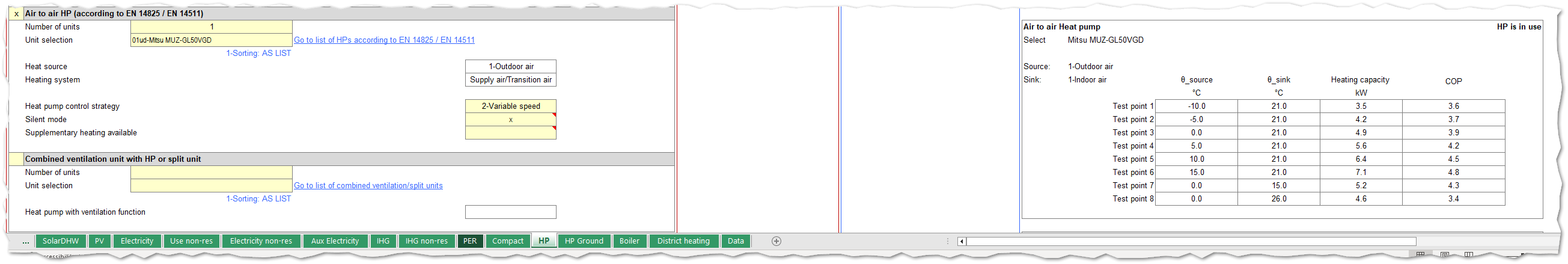

Finally select the heat pump as the heat pump for heating on the heat pump sheet. Notice how I’ve selected variable speed as it’s an inverter unit—and silent mode. The data will pop up to the right. Please check the numbers seem sensible.

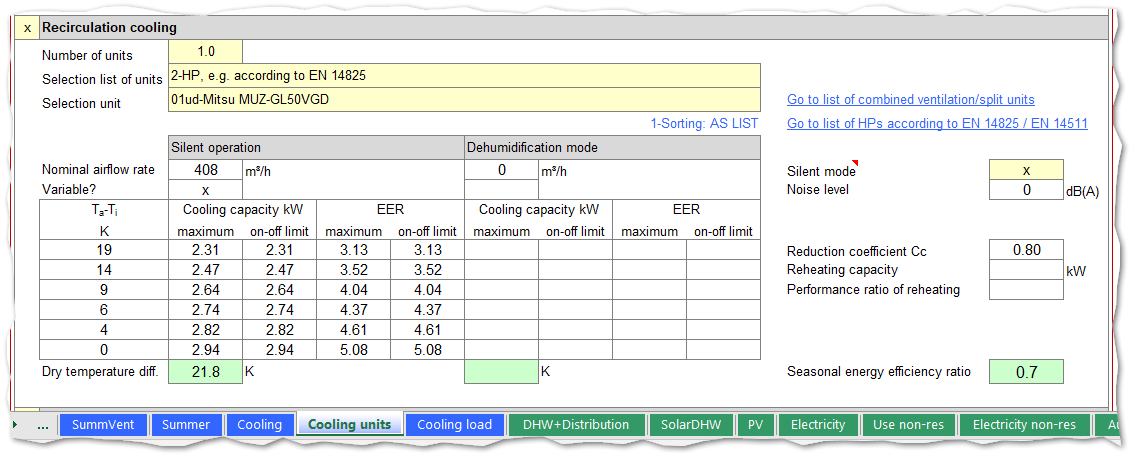

Select the heat pump for cooling on the Cooling Units sheet. Notice I’ve selected silent mode (because quiet is good) and this negatively impacts the unit’s efficiency. Once again, check to make sure the numbers are in the realm of sensible.

Don’t forget to select heat pump on the PER sheet and turn on mechanical cooling on the Verification Sheet.

A sample file with the above data and captions of just the portion of the PHPPv10 is provided in the Certification Guidance folder under Design_Resources. If you don’t have access you can request it at info@sustainableengineering.co.nz.

Any liability for the accuracy and completeness of the contents, data and in particular for any damage or consequences arising from the use of the information presented here is excluded. This is a general explanation and it can not and should not replace specific technical expertise.