PH certification criteria requires that a minimum surface temperature be achieved.

Steps:

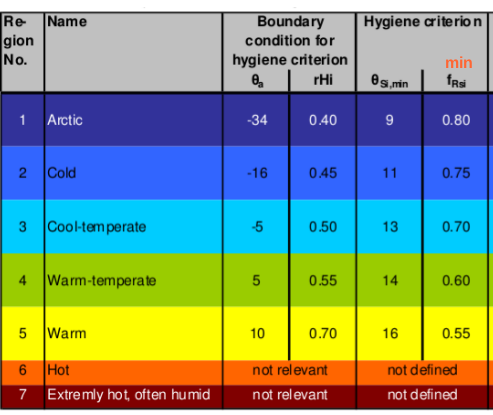

1. Determine the exterior temperature to use – call this the Hygiene External Temperature. This temperature can be any value lower than the internal temperature. I typically use 0 °C as the Hygiene External Temperature and 20 °C as the interior temperature but this is only a matter of convenience as the temperature difference is divided out in step 5 following. PHI typically uses -10 °C outside and 20 °C inside.

2. Calculate your thermal bridge as you typically would per ISO10211 “Thermal bridges in building construction — Heat flows and surface temperatures — Detailed calculations” and using the PHI recommended boundary conditions. Remember it doesn’t matter what temperatures you use for your calculations as long as you are consistent as they are used as ratio’s.

3. To be pedantic you need to redo the PSI calculation per ISO13788 “Hygrothermal performance of building components and building elements — Internal surface temperature to avoid critical surface humidity and interstitial condensation — Calculation methods” but to simplify things PHI recommends: A. Change your thermal bridge model to use the Hygiene External Temperature as the exterior temperature, and B. Change the internal surface resistance to 0.25 m2K/W.

4. Calculate the temperatures throughout your cross section detail and find the minimum temperature that is exposed to interior conditions.

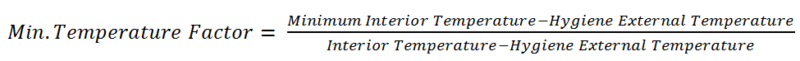

5. Now calculate the Minimum Temperature Factor from:

Note:

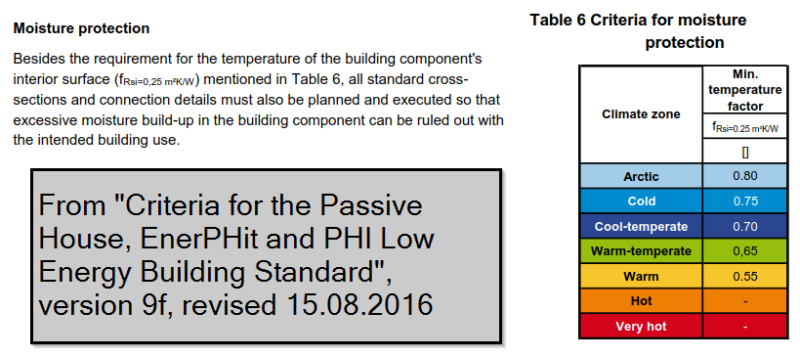

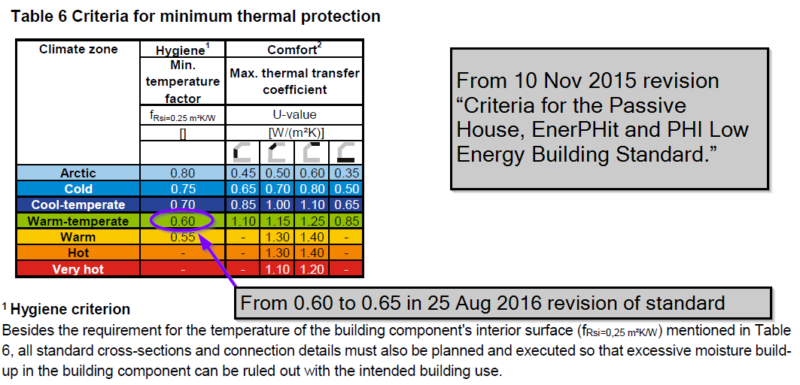

Prior to 10Feb2018 this article had the Table 6 from the 10 Nov 2015 revision “Criteria for the Passive House, EnerPHit and PHI Low Energy Building Standard.” This has the Minimum temperature factor (Frsi) as 0.60 for the Warm-temperate region but the latest revision of the standard has 0.65 as the minimum. Thank you Elrond for pointing this out as I’d missed updating this page.

Prior to 5Oct2017 this article recommended using the following table below which provides the Hygiene External Temperature for each climate region. It noted that this temperature is different than the Thermal Comfort temperature provided in PHPP version 9.6 and newer. I was unable to find a proper reference for the table below but believe it came out of one of the older PHI Passive House Certification Standards. New Zealand ranges from the Warm climate zone in Auckland to Warm-temperate through most of the country to Cool-temperate with only isolated high altitude regions (ski resort cafe) considered Cold climate. In practice it doesn’t matter which temperature is used as the Minimum Temperature Factor is unaffected by this.

Your climate region is shown in the PHPP climate tab (PHPP version 9.3 or higher) and changes with altitude. Note the Frsi minimum of 0.60 for the Warm-temperate region has been changed to 0.65.

Prior to 17Sept16 this article incorrectly stated the exterior temperature to use for the hygiene analysis was the minimum 12 hour annual average. This is incorrect for us in certification to the Passive House Institute standard.

Comments 5

Thanks for this article!

You say, “In practice it doesn’t matter which temperature is used as the Minimum Temperature Factor is unaffected by this”. Is that absolutely true, though? When I change the hygiene external temperature in THERM, the minimum interior temperature changes. This causes small changes in the factor. eg:

Tinternal = 20, Texternal = 0, Tmin = 17.8, Frsi = 0.89

Tinternal = 20, Texternal = -5, Tmin = 17.26, Frsi = 0.8904

Frsi actually goes up in the colder conditions. Is it more accurate to say that “the Minimum Temperature Factor is not largely affected by this”? Just trying to make sure I understand ..

Author

For a one-dimensional thermal bridge it is absolutely true but I can’t mathematically prove it to be true with a two-dimensional bridge. I believe it is. I’d point out the error band in your THERM calc is likely several percent – much more than the 0.04% difference you observed which could easily change with finite element mesh changes.

Author

I’ve recently done more work and for air cavities it does matter a little bit. As the temperature difference increases the convection rate in the air cavities increases and changes the thermal resistance. This is not typically a large effect. In practice this is only important for thermally broken aluminum windows and / or uPVC windows where the air cavities make up a significant portion of the thermal resistance. In these cases we use the minimum 12 hour average external air temperature as the outside temperatures and 20C as the interior temperature.

Also note that for PHPP10 there is discussion on including a location specific custom fRSI requirement which could be less than the current stadnard. This is still in-work.

Q. Do you include any floor coverings for fRsi calcs, and if floor coverings such as carpets are to be excluded, which I assume, then how to go about a floor that has a structural and cosmetic layer of timber.

A. I’d suggest including any coverings with reasonable vapour resistance such as timber or carpet underlay. I’d only include carpet as an additional surface film resistance which would make the result worse if you included it rather than the more common situation of neglecting it.

Thanks for sharing this insightful information