In a Passive House, details matter. It’s important to understand the performance of every element, even tiny ones or those hard to see. Glass spacers are a good example. It’s hard to think of something less sexy. It’s not something your clients will be excited to spend money on. They won’t post photos of them on Instagram. But this material that holds the panes of glass apart in double- or triple-paned glazing units counts a lot towards window performance: 10% on average and more in colder climates. That’s true not least because there’s a lot of it.

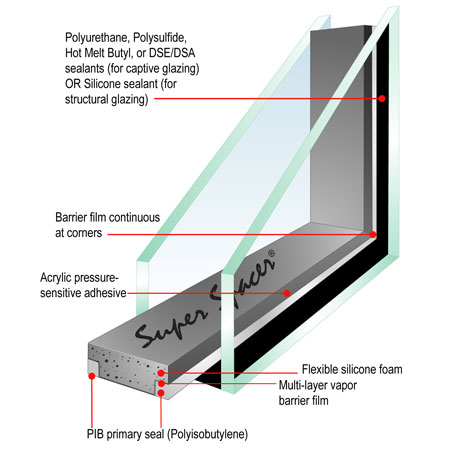

Figure 1: The glass spacer holds the layers of glass apart. A secondary sealant is applied behind them. Image from Quanex.

Let’s take as an example a medium-size building typical of a New Zealand Passive House. It will have about 172 m of frame edge. That typically will translate to 150 metres of glass edge spacer. I ran some calculations based on a thermally-broken aluminium frame 1. A typical warm edge spacer has a PSI-g value of 0.06 W/(mK). Compared to a non-thermally broken aluminium spacer (PSI-g (Ψg) value 0.11 W/(mK)) found in typical Code-minimum projects, the warm edge spacer will reduce annual heating demand by 6% in Auckland, 11% in Wellington and about 17% in Christchurch and Queenstown. That is huge.

Buildings constructed to the minimum legal standard in New Zealand perform so poorly that the contribution of a warm-edge spacer hardly registers. That is a sad fact. But because Passive House buildings typically use just 10% of the heating demand of a regular Code equivalent building, the performance difference between a crappy spacer and a good one is significant.

Fun fact: When Dr Wolfgang Feist designed the very first Passive House in 1991, he pushed the edge of the triple-glazing unit deep into the frame to compensate for the spacers, because the only ones available were low performance alumnium (just like we still use here). This made the frames wider than they needed to be. Modern high-performance warm edge spacers negate the need for this clunky workaround.

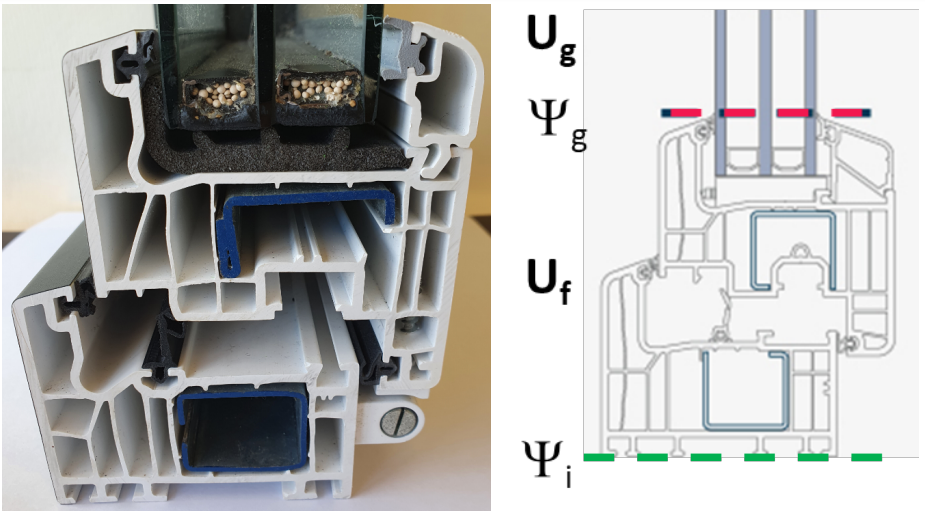

Figure 2: Triple glazing with spacers. The little brown beads are desiccant to remove any moisture between the glass panes when they are sealed in place. The black sealant below the desiccant beads is polysulfide secondary sealant. (Photo/graphic: Jason)

If you’re designing high-performance buildings, make sure that you know what spacer is being used on the glass units you specify. (And what sealant holds it in place.)

In high-performance frames suitable for a Passive House, the spacer selection is fixed by the glazing supplier. The difference between different kinds of warm edge spacers is only about 2% in certified Passive House buildings. Doesn’t sound like much, but some projects need every last percent of savings in annual heating demand (that 15kW/m2/yr is a hard target).

Recently, it took half a dozen emails before I could confirm which secondary sealant was being used to fix the glass spacers in place on a project I was certifying. And this was with a supplier in New Zealand! It turns out they were actually using a hot melt butyl secondary sealant, rather than the standard polysulfide secondary sealant which has higher thermal conductivity. These are the kinds of details you need to be across on a Passive House build.

That difference in sealant changed the spacer performance from 0.036 to 0.029 W/(mK). Again, it doesn’t sound like much, but it caused several Passive House design teams to rejoice as they watched their design’s annual heating demand creep down.

Ask the window supplier to specifically note the details of the warm edge spacer on their window quote: both the brand and model of the warm edge spacer, and the type of secondary sealant. (If it is not otherwise noted, the default assumes it is polysulfide.)

Luckily, almost all spacers being used by industry are PHI Passive House certified and getting the numbers for PHPP is as simple as downloading the datasheet from the PHI website.

Lastly, please do not forget to add 10% to the value from the PHI datasheet unless the frame Uf calculations were specifically done for that exact spacer. This is because the thermal bridge at the glazing edge, the PSI-g, is a function of both the warm edge spacer and the frame edge geometry.

1In a uPVC or timber frame, the PSI-g value typically reduces from 0.08 to 0.04 W/(mK)