20240618 Errata: For PHPP10 style window entries where the entire window net frame size is entered the mullions MUST be entered or else this will not be conservative. Please use a measured (from a drawing) frame width and a demonstratable conservative estimate for the mullion Uf unless you have the calculation.

We’ve certified scores of Passive House projects. We also design them. That combined experience gives Sustainable Engineering Limited’s team perspective and a lot of insight about what is challenging for new designers etc and how to streamline the process to ease that stress.

Drawing on our own experience in doing Passive House design, we’re announcing a small change in our certification practice that relates to the data for windows that must be provided in PHPP.

Windows (and doors) are often the most time-consuming and important part of designing a certifiable Passive House. Previously, mullion widths had to be included in the window component data input into PHPP and provided to us for pre-construction review (the first stage of the certification process). As of now, we will accept PHPP files that do not include the mullion values. However, there may be scenarios where you, as the designer or the client, do want this information to be included. Read on and I’ll explain.

Yes, this Moorish window features a mullion. No this is not a window style we ever expect to see in your PHPP file. Eye candy by Javier Carro, CC BY-SA 3.0.

If mullion widths are provided, it would contribute a tiny bit to reducing required heating demand or load. We’re willing to accept files that skip this information because the impact is very small and it will always err on the conservative side. There is zero risk of this data’s absence incorrectly affecting the certification outcome. To the contrary, it adds a little bit of safety margin.

In the example below, the difference is 0.01 watts per square metre kelvin (W/m2K) in Window U-Value. Tiny, you say! Infinitesimal!

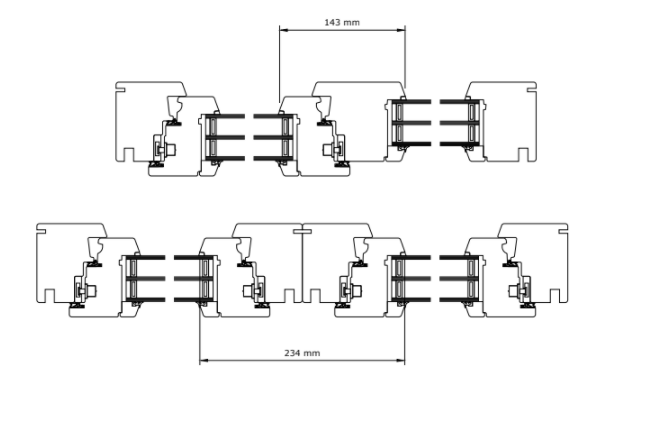

Fig 1. Entries with mullions (above), without mullions (below).

In this worked through example, the Uw value with mullion included is 1.24W/(m2K), compared to 1.25W/(m2K) when the mullion is excluded. Example shows 800mm by 600mm window with equally sized operable Thermadura DesignLine Passive frames. Drawing: Sustainable Engineering Ltd.

But: it accumulates. Across a whole house, it might save 0.3-0.5 kiloWatt-hours per metre squared per year (kWh/m2/year) on the heating demand requirements once you include the slight increase in the glazing area. It is generally the case that heating load/demand are the most challenging targets to achieve in New Zealand climates. So it’s entirely possible that even a 0.3kWh/m2/year saving could make the difference between meeting the certification standard or not. And that’s not infinitesimal at all.

However, not specifying the mullion is not conservative in relation to cooling demand, cooling load or overheating targets. In cases where your project is close to these limits, we may ask you to enter the mullion details.

That important caveat aside, our decision means a designer can save some time by omitting mullion widths at the initial design stage in PHPP (with zero risk to the integrity of the process) and can go back at the end and plug this data in if it will make a necessary difference. You’re welcome.

Note that PHPP will assume either two fixed windows or two operable windows if the mullion data is not provided. The mullion still needs to pass the fRSI criteria, of course. And (for the sake of completeness), we assume the mullion width is less than two times the width of the frame and that the Ug value is lower than the Uf.

Our mission is not simply to certify Passive House projects. We come to work to improve building performance and standards: so that the people who use those buildings can be healthier, happier and more comfortable and so that buildings can contribute to climate change solutions, not add to our problems.

With that in mind, we’re always looking for ways to streamline and clarify the process of Passive House certification. Our clients already have access to a resource folder with tonnes of useful information that can assist with their documentation. For instance, it contains all the data sheets for common insulation products. If clients use the name of the product and the value contained in the data sheet, it is not necessary to send us a copy of the data sheet with the project file. We don’t like unnecessary admin either.

Watch this space, because we’d like to introduce something similar for windows. That would really ease a pain point because getting data sheets out of window suppliers can be taxing, as any designer knows.