Froggy Bottom Otago

Project Team

Architecture & Passive House Design Hiberna Ltd - hiberna.co.nz

Engineer eZED Ltd - ezed.co.nz

Builder Owner and Brooke Harding LBP

Certifier Sustainable Engineering Ltd – sustainableengineering.co.nz

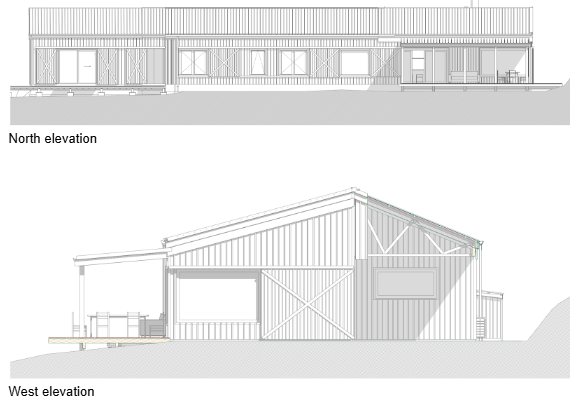

Another strawbale home has achieved Passive House certification, but this is not like the others. Froggy Bottom is a low maintenance, modern home and the only clue to the use of a very local and sustainable building material is the thickness of the external walls.

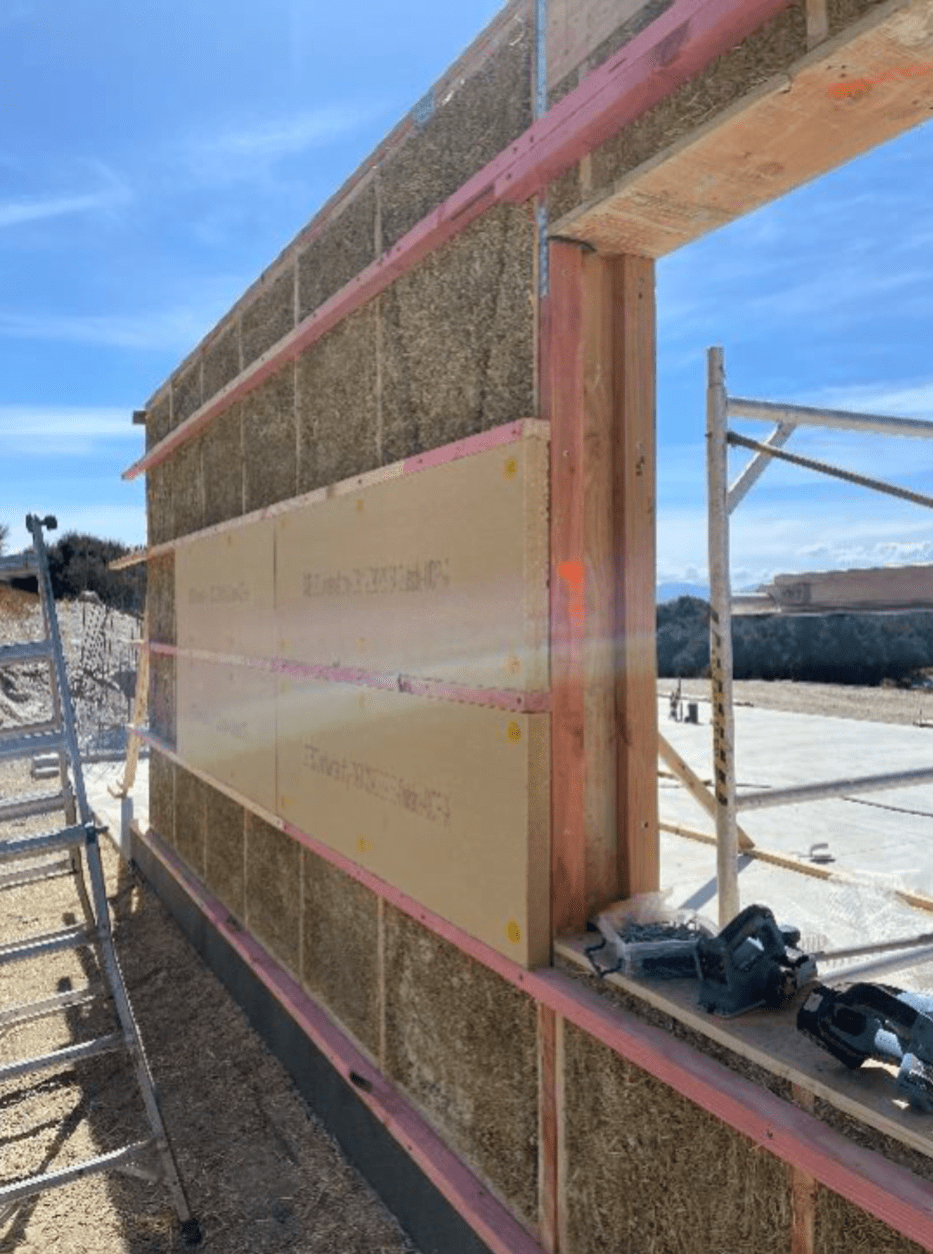

The clients sought out the designer because they knew about the strawbale Passive House she designed and Ben Eyers built, the groundbreaking Hiberna Passive House. Froggy Bottom is the first building in Aotearoa to use prefabricated straw panels, a modular approach to strawbale building developed by Hiberna Modular.

These are a reimagining of a SIP, exchanging petrochemical foam for straw in a timber frame with the earth lime plaster base coat applied in the factory. Specialist experience in strawbale building is not needed. In this instance, the Hiberna Modular team acted as sub-contractors, supplying and installing the panels, but any builder capable of standing up a conventional SIP would be able to work with these instead.

The first use of this prefab product went smoothly thanks to an architectural designer/Passive House designer and engineer both deeply familiar with strawbale construction combined with a motivated and capable owner-builder. The panellised approach plus spray application of plaster slashed construction time compared to a traditional strawbale construction and hand plastering.

The brief was for a ‘modern but rustic’ house with a low environmental impact and low maintenance finishes. The solution was a wall build up of straw panel, to which a skim coat of external earth lime plaster was applied. This provided extra defence against moisture and increased fire resistance (contrary to common assumptions, strawbale buildings are naturally fire-resistant, as the bales are compressed and there is insufficient oxygen to fuel a fire).

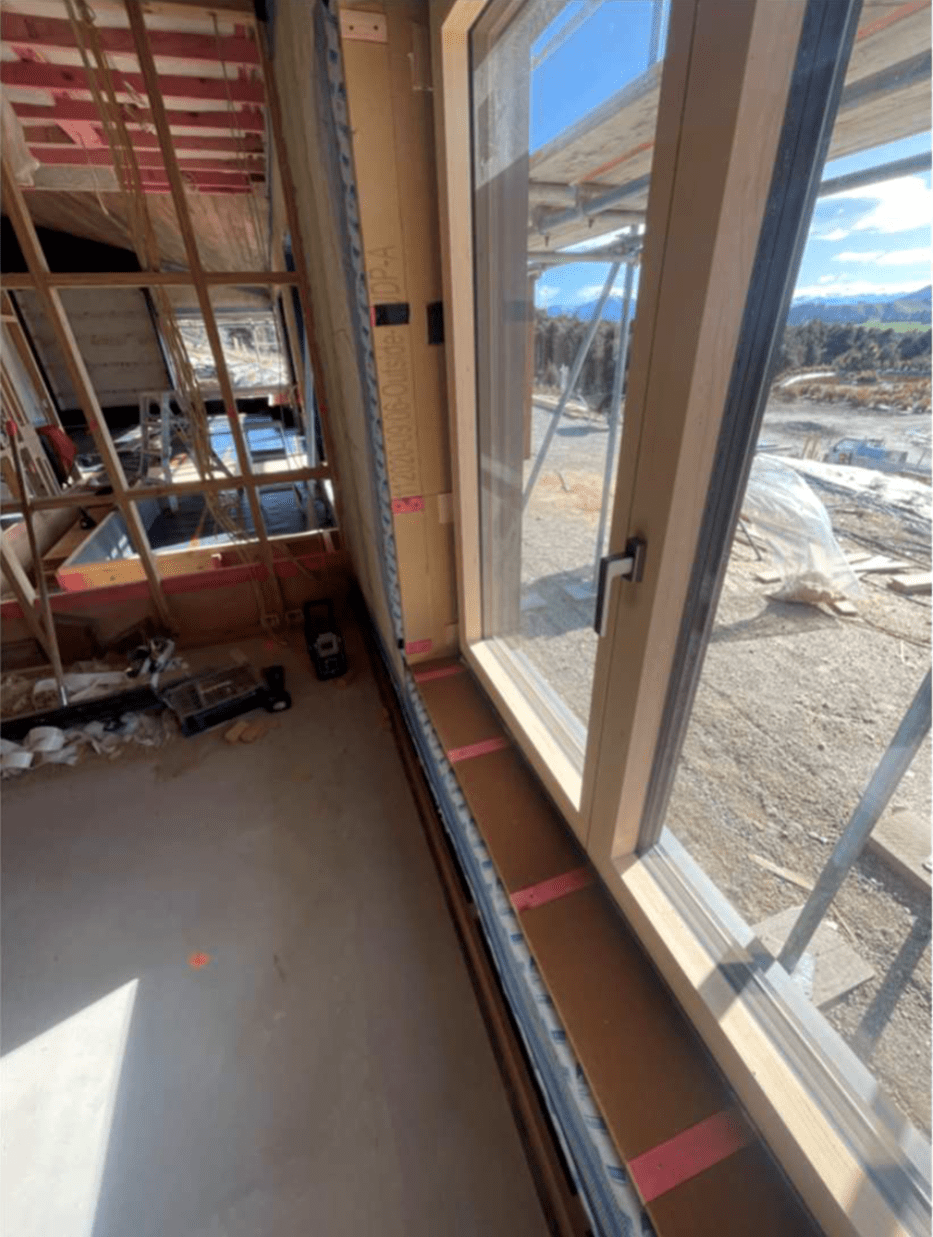

Next was 60mm fibreboard insulation and then a vapour-permeable airtight membrane under the cladding. The membrane could not be applied on the inside of the wall assembly as it’s not a suitable substrate for the earth lime plaster to adhere to. The risk of moisture build up in the walls is reduced when mechanical ventilation is present. Hygrothermal modelling carried out by Sustainable Engineering had anyway confirmed this build up was acceptable, in a far more challenging case (read more on this model here). The final layer of cladding is a mix of corrugated iron and recycled Australian hardwood.

Inside, internal walls are timber framed and all internal walls are sprayed and hand-finished earth lime plaster over wallboard. Unlike earlier New Zealand Passive House strawbale builds, the plaster is not responsible for delivering an airtight building envelope. It does add to thermal mass, to a greater extent than calculated in PHPP, thinks the designer.

The site is steep and required extensive earthworks. The north-facing verandah was initially designed to have a clear light roof. A late change to an opaque roofing material had a significant impact on the heating balance, which the designer worked through. Increasing the R-value of the roof proved the best compensation. Determining the thermal performance of the straw in relation to Passive House performance took some work. Strawbales have a known lamda value but PHI has provided new guidance on values for panelised straw construction.

Thermal bridges were cleverly avoided by the verandah being constructed independently of the house, with posts cantilevered in order to provide full shelter.

This house sits on a beautiful rural site surrounded by regenerating bush, with a pond at the foot of the property inspiring its name. The owners are delighted by how warm and comfortable they felt during the cold Otago winter in their new home.

Passive House Metrics

- Heating Demand13.6 kWh/m2/year

- Heating Load11.4 W/m2

- TFA164.5m2

- Form Factor4.0

- Air leakage @ 50Pa0.3 ACH/hour

- PER demand43.3kWh/m2/year

Passive House Database - TBA

Construction Details Average Values

- U-value External Walls0.17 W/(m2K)(R6.02)

- Straw panel with woodfibre board

- U-value Floor0.10W/(m2K)(R10.22)

- Concrete slab on expanded polystyrene

- U-value Roof 0.11W/(m2K)(R9.46)

- Timber framed roof - timber I-beams or trusses with Terra Lana wool insulation and services cavity insulated with Terra Lana

- U-value Glass0.55 W/(m2K)(R1.82)

- Triple glazing low-E argon filled

- U-Windows0.9 W/(m2K)(R1.2)

- 90mm spruce frame with aluminium skin

- Ventilation Efficiency78%

- Stiebel Eltron LWZ180