—by Jason Quinn and Toby Brooke

MBIE has released the methodology for assessing whole-of-life embodied carbon, the technical advice we’ve been waiting for. This is part of the Building for Climate Change Programme and is intended to be the definitive approach for modelling the embodied carbon of New Zealand buildings.

Building for Climate Change takes a dual approach to reforming the New Zealand Building Code. We expect it will require operational carbon modelling via predictive thermal (or energy) modelling. That provides objective data for reducing buildings’ operation carbon footprint. Second, we expect it will likewise provide direction on embodied carbon modelling to the same end.

We’re glad this advice has been released, although in truth also a bit disappointed about some of the choices MBIE officials have made. Before we get to that, a quick refresher:

Operational carbon is fairly easy to understand. It is the carbon footprint of the energy used for heating and cooling plus plug load (ie all the powered gadgets) in a building. (Think beyond homes; also offices, factories, schools, hospitals—any kind of building.) Operational carbon is the bigger wedge of the emissions pie and the New Zealand building industry is used to the concept, even if its practice is a bit average. (Remember even when we have a fully renewable energy supply in this country, it still won’t be zero carbon, so reducing energy consumption remains the first and vital step.)

Embodied carbon is a more challenging concept. It’s the combined carbon footprint of all the components that go into constructing a building, but also the carbon associated with transporting materials, the construction process, maintenance, disposal at end of life and recovery of any reusable bits. The devil is, as they say, in the detail. MBIE provides a nice illustration of the whole-of-life cycle carbon analysis in its advice, republished below.

Image credit MBIE “Whole-of-Life Embodied Carbon Assessment: Technical Methodology”, 2022.

Some of the complexity is due to how new this whole analysis is. We’ve been fully engaged with it for some time, because changing how New Zealand builds based on operational and embodied carbon data is fundamental to the change we are trying to drive. Sustainable Engineering has run embodied carbon calculations on several projects, going back to 2019. (Jason presented this work at the International Passive House Conference in China; you can watch the presentation here.) We’ve committed to including embodied carbon estimates for all of our initial designs (yes, all of them) from this year.

We were betting on correctly anticipating how MBIE would choose to lay out the rules for embodied carbon calculations in New Zealand. As it turns out we were wrong. That’s unfortunate because our way is better than the route MBIE has decided to go down. That notwithstanding, we will update our methodology to match the MBIE technical guidance. It’s very important the whole sector gets behind a consistent approach to modelling embodied carbon, so we will fall in. It’s urgent that the New Zealand construction sector massively improves its skill and expertise in modelling embodied carbon and we need to all be using the same measuring stick.

For those of you wondering, we expected that MBIE would limit the calculations to embodied carbon up to construction completion (ie A1-A5 only rather than all the way to D), use a 90-year span for the building and specify various technical parameters so that we’re all consistent. Not nailing down all the detail makes it possible to game the analysis in order to make the least amount of improvement. That serves no-one, especially not in the long run.

MBIE’s technical methodology needs to be much more directive if it is to reach its stated objective: “…[T]he methodology provides consistent assessments of embodied carbon, so their results can be compared with each other, and used to make informed decisions.” So expect more official advice to follow, filling in the blanks and ruling out the loopholes that some people will unfortunately go looking for.

At Sustainable Engineering, we’ve had to deal with the heartburn of folks ignoring concrete slabs running out past internal insulation and neglecting the huge energy impact on their H1 energy calculations. We’ve very concerned that this sort of thing will happen with embodied carbon as well. Yes, great table of what must be included—but there are gaps. Is refrigerant leakage accounted for (please, it must be included)? What standard do we use to estimate leakage? (We use the ASHRAE standard in our work.)

I’d like to encourage folks to read the technical guidance. We will update Sustainable Engineering’s initial design process so our base case will match the new NZBC H1/AS1 Code minimum requirement and will now update the embodied carbon section as well. It’ll take us a month or so to roll out for the big changes. We are resigned to smaller changes continuing to trickle through, requiring ongoing modifications to our calculations. It’s simply part of the pain of being an early adopter.

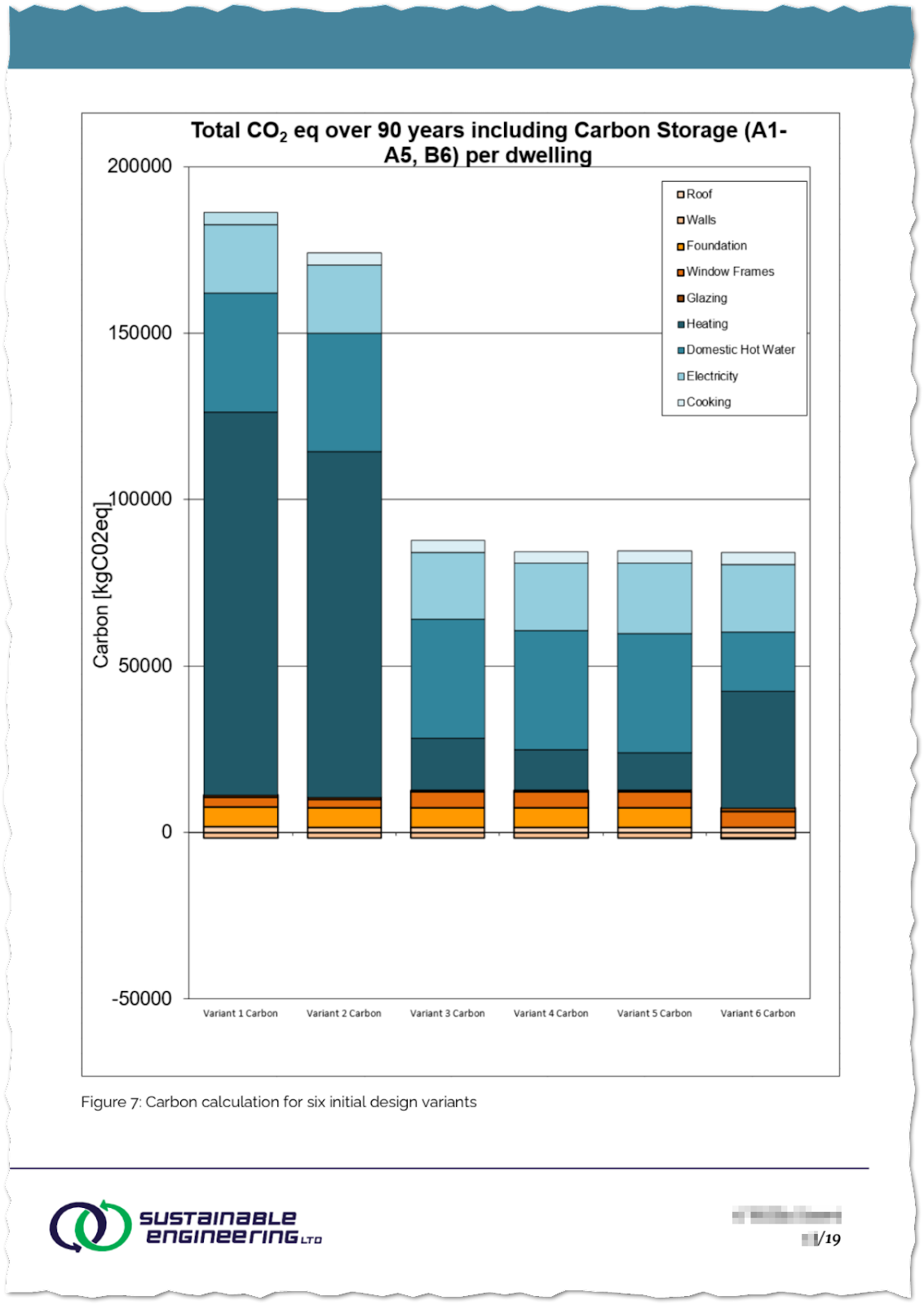

This means that the charts you are used to seeing from us that show six different buildings (as per the example below) will change to match the 50-year period and the whole-of-life cycle carbon analysis and other details contained in MBIE’s technical guidance. One obvious change is that the operational carbon bars will be 5/9ths their current size (we were assessing operational carbon over 90 years, which we still think is the right time scale.)

Image credit: Sustainable Engineering Ltd

We aim to still show all six variations of an initial design on one graph, but it will be hard work to meet MBIE’s technical guidance and example and graph it in a compact and easy-to-read form for our clients.

Take a look at the example graph from MBIE’s technical guidance. It’s rather misleading to show Mod B (the operational carbon emissions) so small. It will almost certainly be larger than the Mod A (embodied carbon emissions) bars. It’s fortunate our technical team like graphs and eat Excel raw before breakfast. We are working on solutions aimed at keeping our stacked bar chart style. (The things geeks fixate on…)

Image credit MBIE “Whole-of-Life Embodied Carbon Assessment: Technical Methodology”, 2022.