There’s still lots of talk about the cost premium to build a detached family home to the Passive House standard and how much that premium is. Let’s not overlook that it is much easier for large buildings to meet the Passive House performance targets. The physics is easier and that usually means it costs less too.

I like to use a very New Zealand analogy. A hulking rugby player can stand around in the cold and be comfortable in a singlet and shorts. Meanwhile, his petite partner is freezing despite being encased in a puffer jacket and cute woolly beanie. Why? Because of the size difference, he’s making more heat inside and losing less proportionally, compared to her.

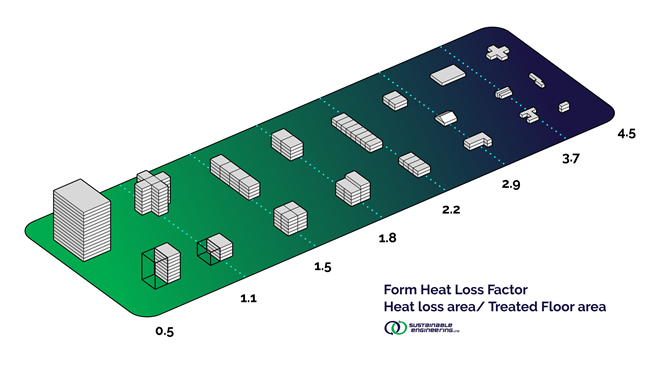

What, this analogy isn’t illuminating? OK, people and buildings are the same: the less surface area to lose heat compared to the internal volume, the easier it is to keep warm. This ratio of exterior surface area of a building to its useful floor area is called the form factor (more formally Form Heat Loss Factor).

Even a medium sized, six-unit apartment block (like Kāinga Ora are building) will have a form factor of around two. A small stand-alone single family home might be about four. The single family home will very roughly need twice the level of insulation to reach the same heating energy performance. (Important caveat: the shape of the building also influences form factor: see below.)

Sometimes when folks ask why it is easier for big buildings to get to Passive House performance, they are actually just talking about dollars, not the physics. On top of the form factor advantage, larger buildings typically have central ventilation, heating and cooling systems (even in New Zealand). Once the building is re-designed to Passive House standards, these systems may cost the same or even less than the standard installs. They will certainly need much less heating and cooling and there are big cost savings there for the life of the building.

For a small building, often no ventilation or heating/cooling is provided*. In this case, when the Passive House MVHR (ventilation) system is added, the cost increases compared to a standard build.

Finally, big buildings are seldom built more than once. They are almost always custom-designed for the site and clients. This is similar to how Passive House is designed (well, anywhere outside of PH precincts in China) so this tends to level the costs considerably. So much so that in Pennsylvania, USA, a Passive House certified housing complex costs no more than a standard build.

*NB for international readers: really, this is normal in New Zealand.